Genesis 180H/HCD and 280H/HCD - Allrounders for Gear Hobbing, with and without Chamfer Cutting

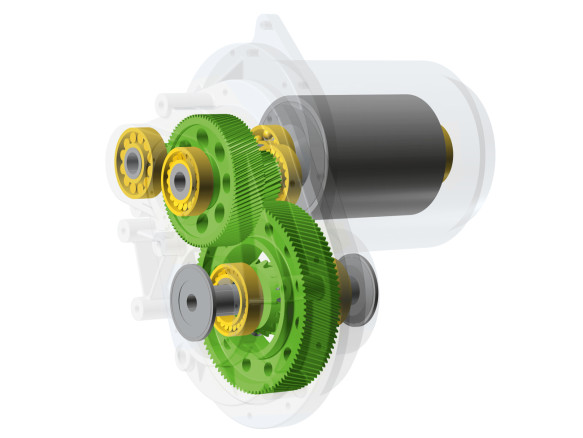

The new machine platform for gear hobbing, optionally available with integrated chamfer cutting. Chamfering is executed in parallel to gear hobbing, perfect for highly productive environments but also suited for the efficient production of smaller batch sizes.

| Workpiece diameter, max. | 280 mm* |

| Module, max. | 6 mm* |

| Axial slide travel, max. | 390 mm* |

| * Different executions available |

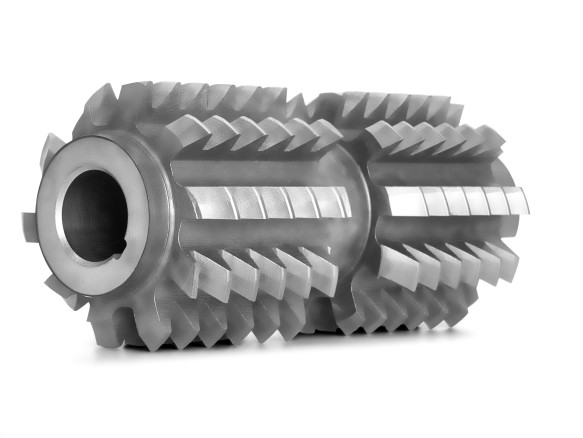

Gear Hobbing for Wet or Dry Machining

The Genesis 180H and 180HCD as well as the 280H and 280HCD machines are designed for dry cutting, but can easily be equipped for wet machining as well.

Uniform and Precise Chamfers

The Gleason chamfer processes produces precise and uniform chamfers with no burrs on the gear face or tooth flank. Learn more about...

Integrated Automation

While the Genesis 180H and 280H are available with a 2-station ringloader, the Genesis 180HCD and the 280HCD features an additional gantry loader or 4-station ringloader to link gear hobbing with chamfer cutting and external automation/storage.

Next Generation HMI

The newly developed GEMS® HMI allows intuitive and efficient operation of the entire hobbing-chamfering process chain.