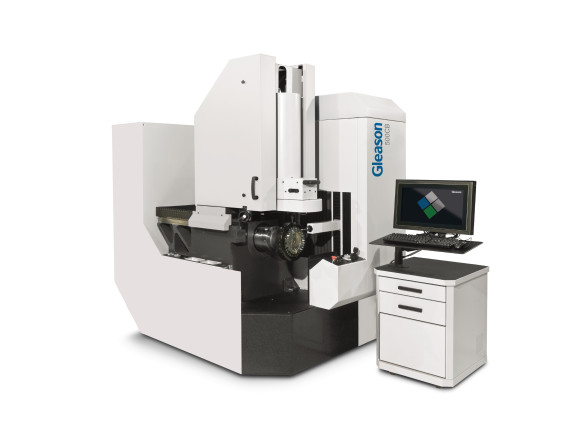

Phoenix 100C - Fast, Precise and Robust Production of Robotic, Power Tool and Similar Size Gears

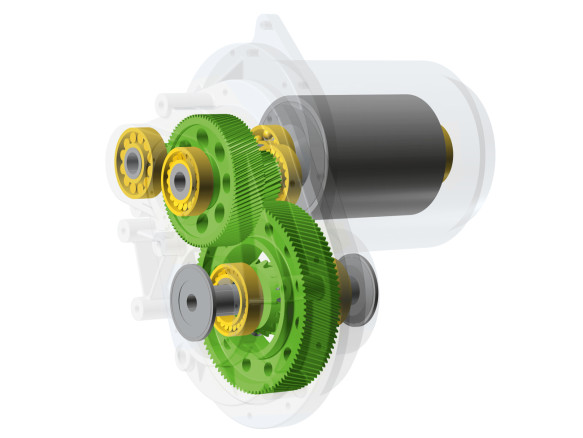

Gleason’s Phoenix® 100C Bevel Gear Cutting Machine has been designed to bring speed, flexibility and ease of use to the high-volume production of precision bevel gears for robotic, power tool, and other applications of similar size.

| Workpiece diameter, max. | 100 mm |

| Range of tooth numbers | 1-300 |

| Cutter diameter (Face Milling), max. | 3.5" |

| Cutter radius (Face Hobbing), max. | 51 mm |

Reliable by Design

The Phoenix 100C is built for maximum reliability, high endurance, and excellent chip containment. The clean and simple design results in easy access and reduced maintenance.

High Spindle Speeds for Smallest Workpiece Diameters

With its high spindle speeds, the Phoenix 100C lends itself for the manufacture of even the smallest workpiece diameters under ideal process conditions.

Maximum Process Flexibility

The Phoenix 100C is configured for wet and dry processing, employing carbide or HSS tools, in solid execution or stick blade cutter system, to suit each application the best possible way.

Easily Automated

The Phoenix 100C is available with an integrated gantry loader with double grippers for fast loading/unloading and can be easily integrated in existing production environments.

Maximum Performance with a Minimum Footprint

With its small footprint of less then 10 sqm/108 sqft (including automation), the Phoenix 100C makes very efficient use of valuable shop floor space.

Powerful Controls - User-Friendly Operation

GEMS® Machine Operating Software provides for easy setup and intuitive operation, including network capabilities for simple and fast integration into modern manufacturing system.