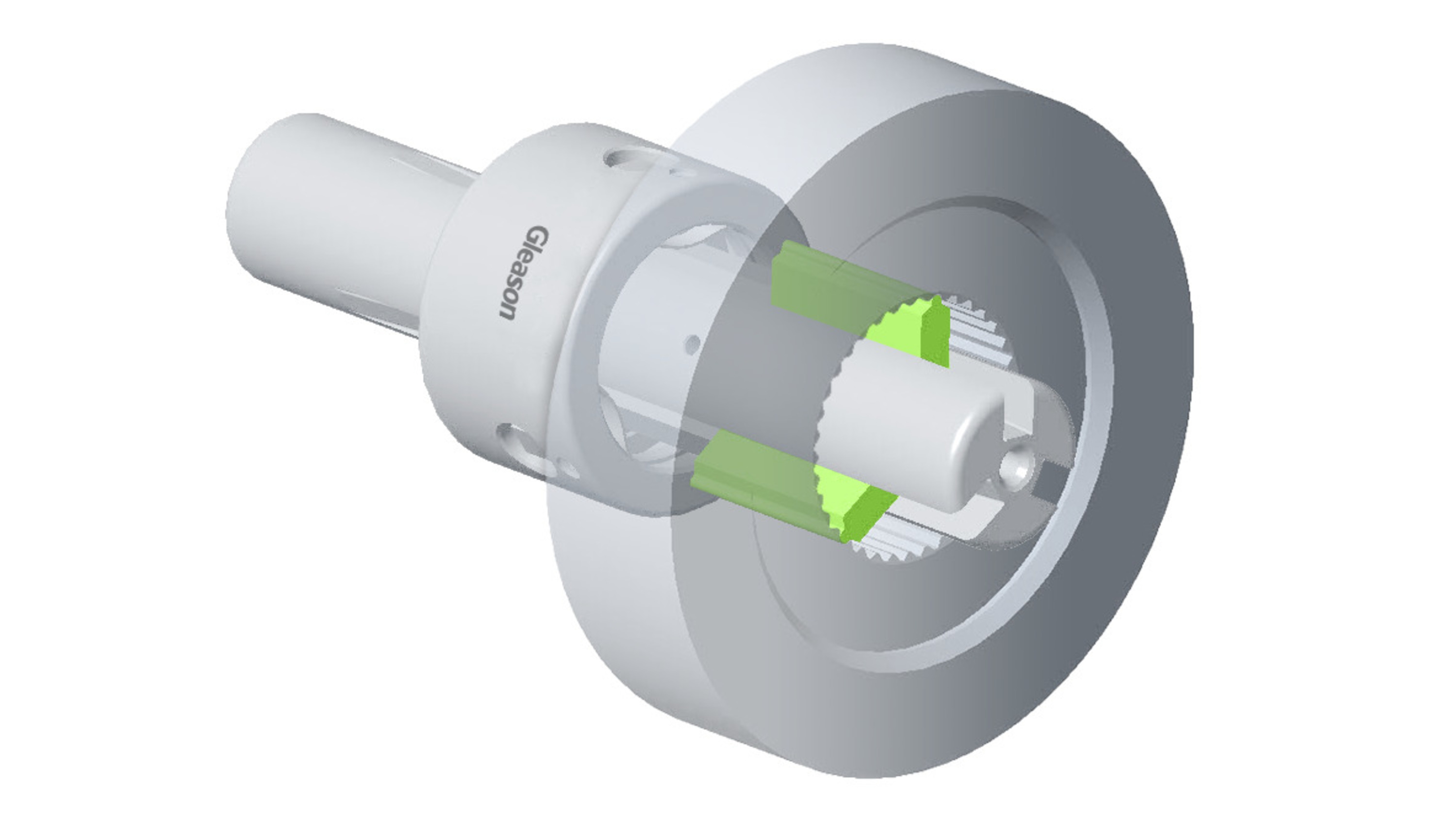

Internal Spline in Bore

LeCount Pitch Spline Mandrels apply the same working principle as LeCount Standard Mandrels, except that a radiused geometry is ground into the contact surface of the three jaws, and the angular position of the jaws is altered as needed based on the number of teeth of the spline. LeCount Spline Mandrels can be made be made to contact the major and minor diameter of a part’s splined bore as well, depending on the customer’s datum structure.

Part Locators

A part locator allows the operator to support the part while loading the mandrel and to position the part on the mandrel consistently without having to re-adjust subsequent parts of the same type. The part locator is attached to the mandrel and spring-loaded detents support the customer part. Note that part locators cannot be added to existing mandrels in use, as this feature must be taken into account during mandrel production.