P90CD - Hobbing and Parallel Chamfer Rolling/Deburring for Short Cycle Times

The Gleason P90CD is designed for hobbing and parallel chamfering/deburring of gears with highest efficiency and minimum cycle time. The present machine is designed for automatic loading, hobbing and chamfering of gears like typically planetary pinions up to Ø60mm. Maximum Ø90mm can be achieved in automatic using special grippers, Ø120mm can be achieved with manual loading.

| Status | New Machine |

| Control |

Siemens SINUMERIK 840D sl |

| Power Supply |

380V / 50Hz |

| Delivery |

Immediate |

| Location | Studen, Switzerland |

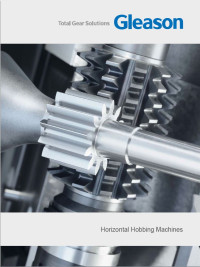

The image is for illustration purposes only. The actual machine may vary depending on features and functions.

Features

This particular machine has the following features:

- Automation

- Special cooler for electrical cabinet

- Protection with access door for hydraulic and pneumatic components

- Hydraulic, semi-automatic counter support

- Power clamping base stroke 32 mm

- Spring operated tailstockside spindle

- Deburring device for P90 special execution with deburring inserts

- Magnetic chip conveyor, 750 mm for P90CD or with ZEA

- Evacuation device for chips for dry hobbing

- 3 air blowing nozzles for dry hobbing

- Noise-reducing equipment for dry hobbing

- Nozzle for chip evacuation, workpiece-specific

- Energy saving tool

- Software for fault diagnostics and extension for X-Z corrections

- Internet diagnostic system (Gleason Connect®) via port opening

- Dialogue programs for "X-Y Correction", "C-Z Correction", "Damaged hob positions"

- Shift data storage

- Safety retraction

Technical Data

| Workpiece diameter, max. |

100 mm |

| Module, max. |

3 mm |

| Axial slide travel, max. |

400 mm |