Open to New Ways? Advanced Analytics in No Time!

Laser probing collects massive amounts of data much faster than conventional tactile probing. Now, complete point clouds are available for advanced analytics at a fraction of the time required by traditional measuring.

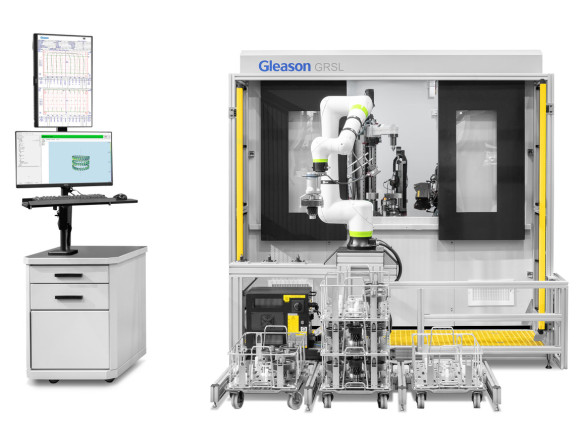

GMSL Series - Multi-Sensor Inspection Including Laser Technology

Gleason Gear Metrology Systems with Laser Technology provides gear manufacturers with a single, compact, reliable and easy-to-operate inspection solution to apply a wealth of measurement and analysis methods - including revolutionary analytics for both R&D and production applications.

| Helix angle |

0 to 90° |

| Module | 0.4* to 18 mm |

| Workpiece length, max.** | 500 mm |

| Workpiece diameter, max. | 300 mm*** |

| * 0.2 optional |

|

| ** extended z-axis optionally available |

|

| *** diameter capability optional up to 3,000 mm |

Advanced Analytics with Laser Technology

Apply laser scanning technology and get access to revolutionary analytics, for faster development of increasingly complex gears.

3D Laser Measuring - for More than Just Gears

3D laser scanning bears significant benefits for the reverse engineering of complete parts including gears and other geometries. GAMA graphical interface will show variations from nominal data depending on the defined tolerance band.

Become Versatile

The GMSL Series is equipped with high accuracy 3D scanning probes with a broad range of styli, including a stylus calibration library and optional automatic probe and sensor changer.

Measure Surfaces

GMS offers a wide range of surface roughness measurements, meeting the most common roughness parameters as defined in DIN, ISO, ANSI and more.

Measure Gear Tools

GMS systems handle inspection of many gear cutting tools including hobs, shaper and Power Skiving cutters, stick blades and shaving tools. Depending on size, even most broaches and rack cutting tools are accommodated.

Get CMM Capabilities

Enjoy 3D measurement and analysis capabilties typically performed by a CMM.

Advanced Operator Interface

The ergonomically designed work station is complemented by an Advanced Operator Interface with video conferencing, voicemail messaging and QR barcode reading including monitoring of the machine temperature and environmental conditions.

Be Fully Compatible

GAMATM 3.1 or 3.2 Applications and Control Software is fully compatible with Windows and connects easily to customers' servers. GAMA includes SPC data acquisition software and Gleason Connect® Global Support Services.

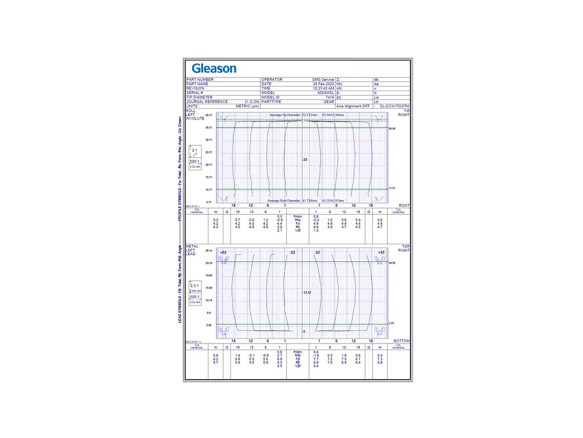

Quantum Leap in Gear Noise Evaluation

KTEPS Kinematic Transmission Error Prediction Software offers a revolutionary method of showing tooth flank surface deviations in relation to their orders, for simple and fast gear noise evaluation.

Fine Pitch Gear Inspection

Fine pitch plastic gears can be inspected without master gear and double flank composite inspection, even in cases when tactile probe tips do not fit into the gear tooth gap to check the entire profile.

For Plastic Gears check:

Close The Loop

Easily networks to Gleason Grinding, Power Skiving and Honing Machines like the GX Series, 300TWG, 100PS, 300PS or 150SPH in a Closed Loop with automatic, corrective feedback to the production machine.