Genesis GX Series - The Grinding Solution Designed for Highly Productive Environments

Genesis® 200GX and 260GX Threaded Wheel Grinding Machines combine maximum productivity with minimized idle and setup times. The GX Series is the ideal solution for customers in high-productivity, high-quality environments.

| Workpiece diameter, max. |

260 mm |

| Module, max. |

4 mm |

| Shaft length, max. | 500 mm |

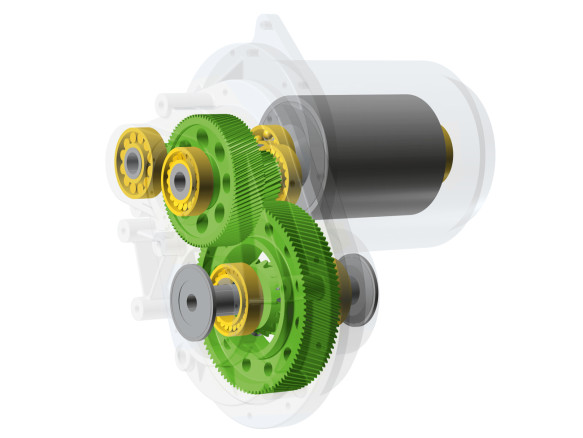

Double Spindle Machine Concept Minimizes Idle Times

Time consuming loading and unloading is executed in parallel to the grinding process.

Twist-Controlled Grinding

Achieve different amounts of twist on left and right flanks in double flank grinding mode to address twist or bias when grinding helical gears with lead modifications without impact to the grinding time.

Setup with One Tool

The setup process including tools, workholdings and automation adaption is changed with only one tool.

Fully Automated Workflow with the First Part Cycle

After mechanical setup, the GX Series completes all the necessary steps needed to have the first workpieces successfully ground.

Polish-Grinding or Fine-Grinding

Create gears with a quality surface finish by using a two-zone grinding wheel consisting of two sections: one for grinding and one for polishing/fine-grinding, matching the individual requirements of each process.

VRM Grinding

Influence the typical surface texture of ground gears with the VRM feature (Variable Rate Method) to achieve surface textures with improved noise emission characteristics.

Closed Loop Ready

Create a direct link between your Gleason Metrology System inspection center and your GX machine. The grinding machine will compare the data transmitted with the nominal values and automatically calculate the corrections required.

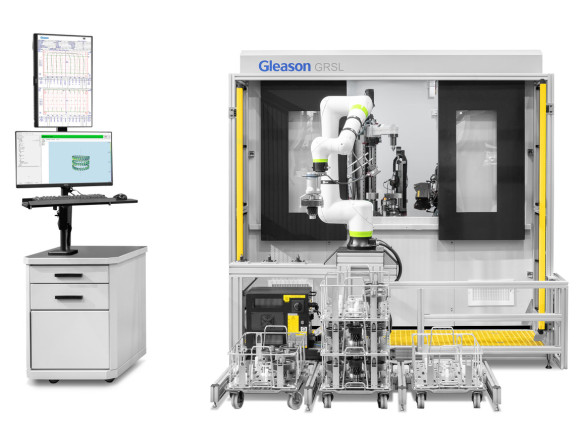

Automation that Fits Your Needs

Accomodate two different automation solutions: conveyor or palletizer. For both systems we offer fully integrated Gleason solutions or interfaces to third party suppliers.