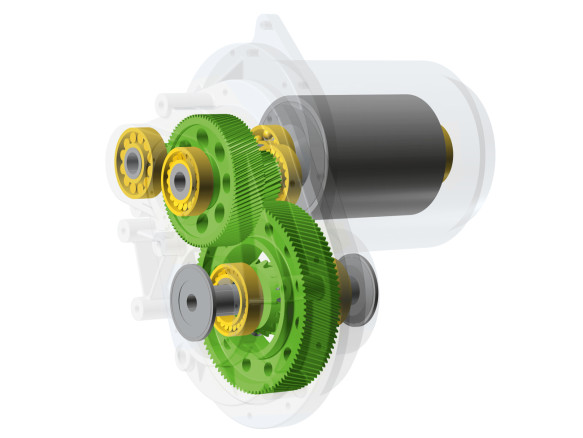

Phoenix 600G - High Quality for Truck Sized Bevel Gears

Higher speeds and increased torque, combined with shorter and faster motions dramatically increases productivity.

| Workpiece diameter, max. | 600 mm |

| Range of tooth numbers | 1-300 |

| Wheel diameter, max. | 20" |

Built to Last

High quality, greater accuracy and repeatability due to rigid monolithic machine column design.

Highly Versatile

Flexibility and versatility for different part geometries, such as spiral, hypoid, straight bevel, face clutches, face gears, hypoloids and super reduction hypoids.

First Part Checking

Operators like the integrated first part measuring cycle with its automated correction feature for easy and fast setup until the first part is ground to perfection.

Extremely Compact

Larger parts produced in a very small space - 35% smaller footprint than any other machine in its class.

Easy to Operate

Equipped with powerful Fanuc 30i control and Gleason's user-friendly software to empower even less experienced operators.

Quick-Change Coolant Pipe Design

For faster changeover and higher process stability.