You are cordially invited

Join us at Booth E6007 in Hall 6 at JIMTOF in Tokyo, Nov 8-13, 2022.

See the latest in design, manufacture and inspection of gears and meet the gear technology experts to discuss your specific applications.

We look forward to welcoming you in person.

From Design to Manufacture

The KISSsoft® Release 2022 provides many new features for the design and simulation of gearbox elements and complete transmissions – try them out at the show!

Constant Quality and Reduced Tool Cost

Power Skiving with integrated cutter resharpening eliminates idle time for cutter change, provides constant quality results, reduces tool cost, and minimizes cutter inventory and logistics.

Fast, Agile Production of Truck-Size Gears

New Phoenix® 500C Bevel Gear Cutting Machine brings speed, flexibility and ease-of-use to medium and high volume production of precision bevel gears for trucks, buses, and other applications of similar size.

Excellent Surface Qualities

Employ Super Finishing for excellent surface qualities or Combi Honing to finish timed, stepped e-drive pinions in one setup.

Gears with Mirror-Like Surfaces

Genesis® 260GX Threaded Wheel Grinding Machine features Twist-Controlled Gear Grinding, VRM Grinding, as well as Polish and Fine Grinding for an unmatched quality surface finish.

Gear Inspection at Submicron Level

Measure submicron surface finish with a skidless probe, analyze waviness in profile and lead, and analyze gear noise with sophisticated software tools, such as Advanced Waviness Analysis and KTEPS.

Quantum Leap in Gear Noise Evaluation

KTEPS Kinematic Transmission Error Prediction Software offers a revolutionary method of showing tooth flank surface deviations in relation to their orders, for simple and fast gear noise evaluation.

Gear Inspection at the Speed of Light

Experience gear inspection at the speed of light with the 300GMSL Gear Metrology System. Laser scanning provides the data for revolutionary, real-time analytics for fast development of complex gears and minimum noise gearboxes.

More Precision, Faster Change

Meet the latest hydraulic and mechanical workholding developments for rotary parts and many different applications like turning, milling, hobbing, chamfering, Power Skiving, shaping, and inspection.

To the Last Micrometer

Grinding and honing applications can be often optimized to raise quality and/or save cost. Find out how Gleason dressing tools will support higher productivity and constant quality results. Meet our experts to discuss your application in person.

Harder and Faster

Gleason’s new line of Carbide Power Skiving and Shaper Cutters provides excellent productivity and tool life. Available for all Power Skiving machines.

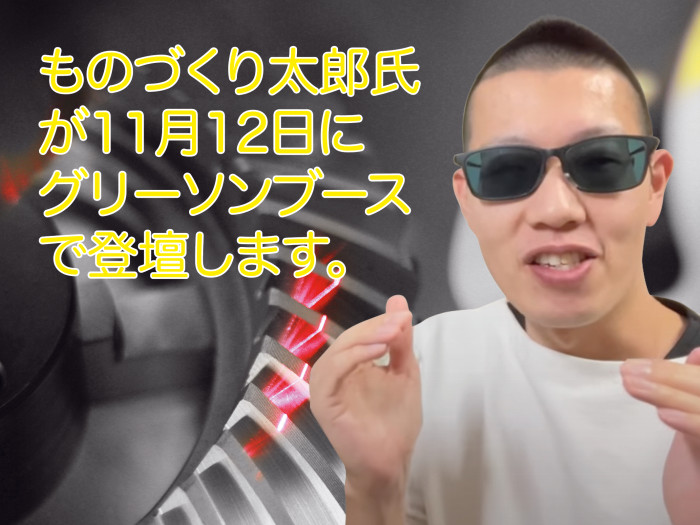

Meet the Manufacturing Man

Meet YouTuber ものづくり太郎チャンネル @monozukuritarou exploring the Gleason Booth and exhibits live on Nov 12:

1st session 11:30 -12:00

2nd session 14:00-14:30

Or watch his report on YouTube right after its release.

Get Your Free Ticket Here!

Enter your data and we send you a free code which you can redeem at the official JIMTOF website for your free ticket.