| Technology | Gear Machines |

| Level | Advanced |

| Processo | 5-Axis Gear Machining, Bevel Cutting, Bevel Grinding, Bevel Curvic Coupling Grinding, Bevel Lapping, Bevel Roll Testing, Bevel Quenching, Bevel Blade Grinding, Bevel Blade Inspection, Bevel Cutter Build |

| Course Number | B-GGA71 |

| Class Duration | 4.5 days |

| Number of Participants | 3-12 / Online 50 |

| Training Location | Online, Rochester, NY, USA, Ludwigsburg, Germany |

Price on Request

Price on Request

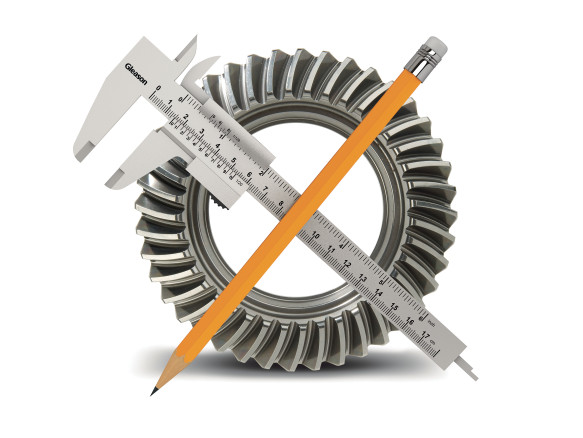

Applied Bevel Gear Engineering

Continuation of subjects covered in the Fundamentals of Bevel Gear Design. An in-depth series of lectures, discussions and hands-on workshops using Gleason GEMS® Design bevel gear design and manufacturing software. A working knowledge of the theory of tooth contact pattern development and the use of Gleason GEMS® Design software for Tooth Contact Analysis (TCA), undercut check, and machine settings.

Topics

- Introduction to Gleason machines.

- Bevel gear design and dimensions.

- Explanation of software input.

- Introduction to TCA.

- Calculation of TCA and machine summary.

- Explanation of machine summary items.

- Tooth contact analysis under load (LTCA).

- The Gleason Completing System (design, TCA, development).

- Tooth contact, deflection and fatigue testing.

- Methods of hard finishing bevel and hypoid gears.

Upon Completion

A certificate is issued with successful completion.

Note

Please use the shopping cart to select the location, language and date. The selection in our shopping cart will not trigger an order, but starts a request for quotation with your preferred date (unconfirmed). The Gleason Academy team will contact you with further details.

This class is also available online (only English). Online classes are conducted in sessions with max. 4 hours per session, per day, including breaks. Sessions can be chosen as required, either on consecutive days or based on a reoccurring weekly schedule. We use “Zoom“ as video conferencing and presentation platform.