Tools for Threaded Wheel Grinding & Dressing

Gleason’s line of grinding worms, dressing discs, and dressing rolls is fast expanding to meet the demand for more productivity, flexibility and the highest quality standards.

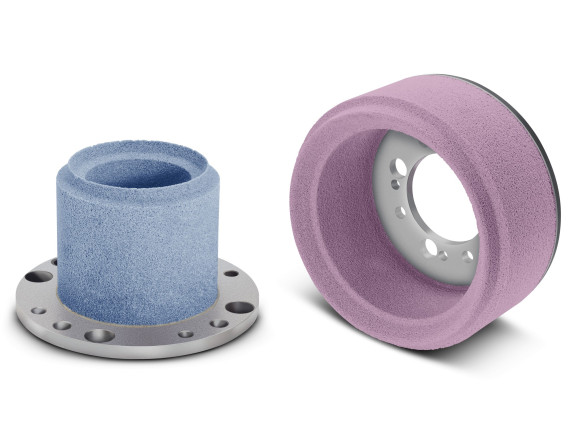

Dressing Discs and Dressing Rolls - for Flexible and Highly Productive Applications

Gleason offers dressing discs, rolls and bars for different gear manufacturing applications. Our program covers solutions to dress threaded wheel grinding worms for involute and non-involute gears in the range of Module 0.5 to 8 mm. Depending on the required flexibility and your production needs, we have the right solution for prototype or high volume production.

Design Competence

The geometric design and the plating of the high-precision tool is based on multiple years of experience with Gleason Profile and Threaded Wheel Grinding Machines as well as in our own gear tool production. Tool designs reflect the cutting operation prior to the actual grinding process, for example, gear hobbing – to achieve optimum results, especially in the critical root area of the gear, it needs to be ground.

Best Production Quality

High quality standards begin with the production of a precise tool body followed by the diamond plating process in our own modern galvanic department. The diamond layer once applied is finished by special grinding processes to achieve the correct contact ratio. Finally, all tools must pass our stringent quality control including the proper (customer-specific) documentation.

Replating of Dressing Tools in Order to Optimize Your Cost per Piece

All positiv plated diamond tools can be replated multiple times to extend their life cycle in the production process. Replating dressing tools is available worldwide.

Grinding Worms for Gears

Gleason Grinding Worms are available for high-performance grinding, twist-controlled grinding and polish grinding. We choose the right specification for your application from the wealth of available grit material and bonding types.

Polish Grinding - Threaded Wheel Grinding to Perfection

Grinding worms are for specific processes such as sandwich wheels for polishing grinding. Gears ground with a Gleason Polishing Grinding Worm - the technology continues to be on the rise.

We provide Customized Solutions

If desired we can support you with machine setup and run off of your new grinding worm and/or dressing tool to achieve maximum tool life, the desired quality and maximum efficiency.