300GMS nano - Inspection at Submicron Level

Gleason 300GMS® nano Gear Metrology System combines all the latest inspection capabilities into a single, compact platform for the complete inspection of gears up to 300 mm in diameter and shafts up to 500 mm in length, fine pitch gears as small as .2 module. Repeatability and reliability exceed VDI/VDE2612 standards for form measurement up to factor 5.

| Helix angle |

0 to 90° |

| Module range | 0.2* to 18 mm |

| Workpiece length, max.** | 500 mm |

| Workpiece diameter, max. | 300 mm |

| * 0.2 option | |

| ** extended z-axis optionally available |

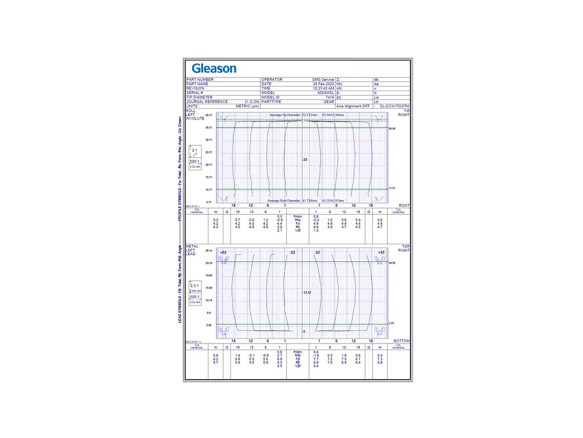

Evaluate Waviness on Submicron Level and Analyze Gear Noise

Measure submicron surface finish with a skidless probe, analyze waviness for profile, lead and pitch, including noise analysis with sophisticated software tools.

Resist Thermal Deviations and Vibrations

Highly accurate precision guides, laser-mapped with Invar scales and an air-cushioned, no slip-stick table create the reference in precision inspection. Optionally, choose the GMSP Series with its patented machine base with super-dampening by air-cushions.

Become Versatile with Smart APC

The GMS Series is equipped with high accuracy SP25 3D scanning probes with a broad range of styli, including a stylus calibration library. Optionally, get the Automatic Probe Changer (APC) with 6 or 9 stations and sensor-monitoring of APC positions to avoid probe pad collisions.

Measure Surfaces

GMS offers a wide range of surface roughness measurements with evaluation meeting the most common roughness parameters as defined in DIN, ISO, ANSI and more.

Get CMM Capabilities

Enjoy 3D measurement and analysis capabilities typically performed by a CMM, ideally suited for rotary symmetrical parts.

Inspect Gear Tools

GMS systems handle inspection of many gear cutting tools including hobs, shaper and Power Skiving cutters, stick blades and shaving cutters. Depending on size, even most broaches and rack cutting tools are accommodated.

Benefit from Trendsetting Operation

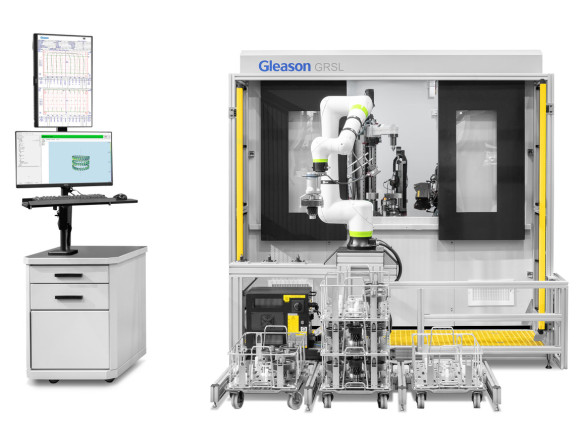

The Human Machine Interface (HMI) meets factory space allotment and operator preferences. With the Advanced Operator Interface (AOI) record video, telephone and voice messages, monitor environmental conditions and read bar and QR code information directly into the machine.

Be Compatible

GAMATM 3.1 or 3.2 Applications and Control Software is fully compatible with Windows and connects easily to servers. GAMA includes SPC data acquisition software and Gleason Connect® Remote Services.

Quantum Leap in Gear Noise Evaluation

KTEPS Kinematic Transmission Error Prediction Software offers a revolutionary method of showing tooth flank surface deviations in relation to their orders, for simple and fast gear noise evaluation.

Design, Manufacture, Measure in a Smart Loop

Directly feed back inspection results to KISSsoft design software for fast and efficient design adjustments in the prototyping phase. Easily network selected Gleason manufacturing machines with GMS Metrology Systems to achieve continuous high quality and productivity.