300PS - The Universal, Easily Automated Machine

Well suited for the highly productive manufacturing of cylindrical internal and external gears with outstanding quality and significant reductions in cost-per-piece.

| Workpiece diameter, max. |

300 mm |

| Swing diameter, max. | 450 mm |

| Module, max. | 4 mm |

Maximum Stiffness

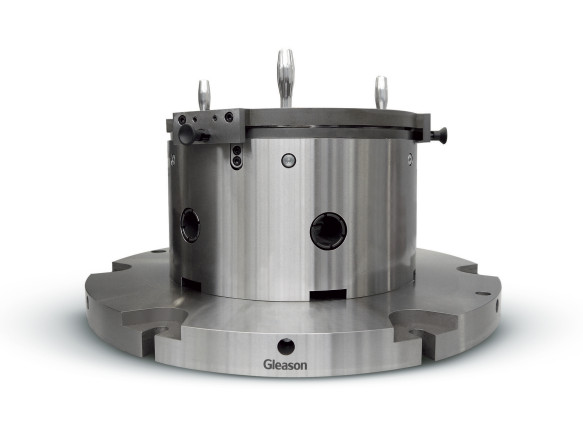

The complete Power Skiving system consists of machine, tool and workholding and is designed for extreme stiffness.

Simple Setup

Modular workholding with quick-change elements makes setup easy - for different workpiece diameters or face widths.

Convenient Operation

Operators highly appreciate the convenient tool and workpiece change within the generously designed workarea.

Choice of Automation Solutions

Available with ring loader, CNC grippers and a standard revolving buffer magazine, the PS Series can be automated to customer-specific requirements like robotic or gantry loading as well as chain magazines.

Automated Tool Change

Power Skiving tools can be changed automatically to minimize change time, machine several gears on a workpiece or to complete one gear using different tools.

Integrated Resharpening for Constant Quality and Reduced Tool Cost

Cutter resharpening in the machine eliminates idle times for cutter change, especially beneficial for large batches. Benefit from constant quality results, reduced tool cost, inventory and logistics.