100H Series - High Speed Hobbing with Optional Integrated Chamfering/Deburring

The 100H Hobbing Machine Series is the next generation of the well-known P90 Series with improvements in design, functionality and operator inferface. This hobbing machine and its variants handle a wealth of geared profiles up to a workpiece diameter of 120 mm, module 4 and a shaft length of 1200 mm.

| Workpiece diameter, max. | 100/120* mm |

| Module, max. | 2.5/3/4 mm |

| Axial slide travel, max. | 400/800* mm |

| * Option |

Short Cycle Times

Extremely fast cutting and processing times make the 100H series ideally suited for the large batch production of gears and pinions.

Integrated Chamfering/Deburring

The model version 100HiC features an integrated chamfering/deburring unit applying chamfer rolling to eliminate burrs on tooth flanks.

Hobbing and Parallel Radial Chamfering on 100HCD for Workpieces with Interferences

Machine is enhanced with an additional radial chamfering station with chamfer cutting which works time parallel to the hobbing process.

Hobbing of Shafts

Up to 1200 mm with the extended 100HL.

Suited for a Wealth of Applications

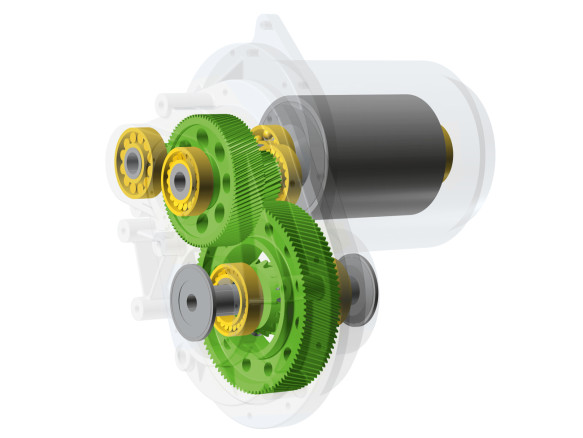

Pump gears are just one of many different applications that the 100H is well adapted for.

GEMS Operating Software for Ease of Use

Mainly equipped with the GEMS® Operating Software, the 100H series provides for intuitive and graphic operation, guided setups and interactive programming via touch screen.

Steering Pinions, Worms and Worm Gears

The 100H is suitable for the production of worm-type workpieces, including the hard finishing of steering pinions by skive hobbing.

Quik-Flex Horizontal Workholding

The 100H series can be optionally equipped with the Quik-Flex® Horizontal Workholding for fast change over.

Variety of Automation Systems

100H Hobbing Machine Series can be equipped with a variety of automation systems, including robots, gantry loaders, and custom production flows.

Auxiliary Processes and Workpiece Storage

Gleason Automation Systems provides modular auxiliary processes like washing or marking, as well as different workpiece storage solutions.

Get Exactly the Machine you Need

The 100H series is available in different models for optimum adaption to job-specific tasks or to meet the universal needs of the job shop.