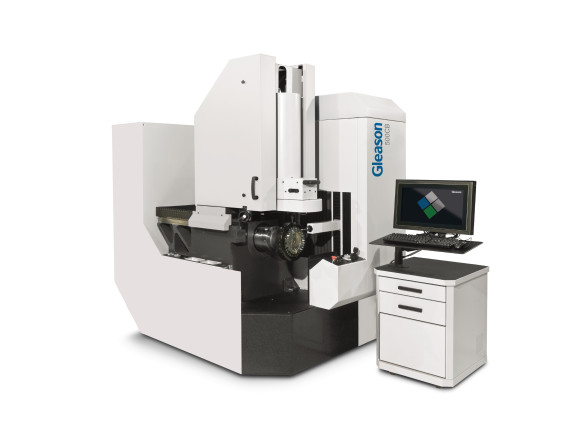

Phoenix 600HC - Fast and Economical Production of Truck-Size Bevel Gears

The Phoenix® 600HC has been developed for manufacturers of bevel gears as large as 600 mm in diameter to feature a host of benefits for the production of truck, bus and industrial gearbox applications.

| Workpiece diameter, max. | 600 mm |

| Range of tooth numbers | 1-300 |

| Cutter diameter (FM), max. | 18" |

| Cutter radius (FH), max. | 210 mm |

Reliable by Design

The Gleason 600HC is built for maximum reliability including simplified guarding and excellent chip containment. The clean and simple design results in easier access and less overall maintenance.

Unsurpassed Productivity

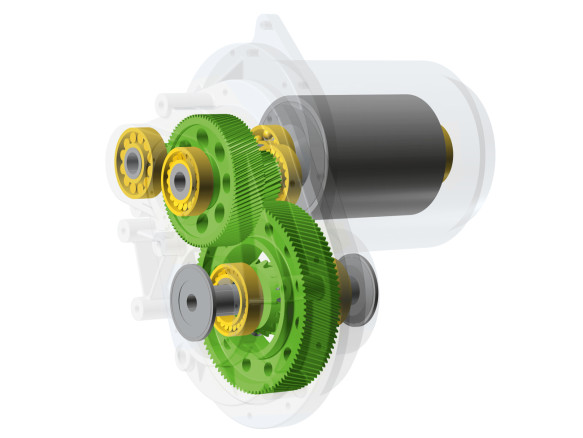

Direct-drive, high speed and high torque motors on the cutter and workhead spindles provides optimum performance for PowerCutting® - in dry or wet conditions.

Versatile

Capable of both face hobbing and face milling; plus cutting of straight bevel gears, face gears, face clutches, power skiving and unimillTM.

Easy Changeover and Operation

The 600HC's column design brings cutter and workpiece closer to the operator allowing for easy access as well as easier loading - manually or automatically.

User-Friendly Control

The Gleason HMI greatly empowers even less experienced operators to create programs and operate the machine more productively. The 600HC runs with the latest Fanuc 30i control.

Built-In Intelligence

Embedded condition monitoring alerts you of potential future issues. Problems are resolved before they happen.

Worry-free Automation Solutions

Flexible machine concept to integrate different automation and part handling solutions, provided inhouse by Gleason Automation Systems, or by third party automation suppliers.